Amokabel Def Stan Cable

Amokabel’s Def-Stan cable, supplied by Aerco, is designed to meet the stringent requirements of UK Defence Standards. Manufactured for durability and reliability, these cables are suitable for military, aerospace, and other high-performance applications where safety and efficiency are critical. With a focus on high-quality materials and compliance with industry specifications, Amokabel’s Def-Stan cables provide a dependable solution for demanding environments.

Download the Defence and Military brochure ![]() Amokabel Defence and Military

Amokabel Defence and Military

Download the Brand Rex NXT99 Defence brochure ![]() Amokabel Brand Rex NXT99

Amokabel Brand Rex NXT99

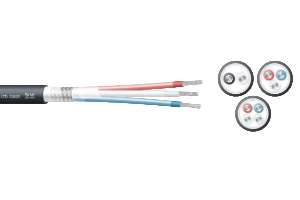

NXT99 - 600V Multi Core Screened & Sheathed Def Stan 61-12 Part 18:

- Stranded Tinned Annealed Copper

- Extruded Dual Layer Polymer

- Insulation Flame retardant dual layer insulation

- Temperature Rating -50°C to +105°C

NXT99 - 600V Multi Core Unscreened & Unsheathed Def Stan 61-12 Part 18:

- Stranded Tinned Annealed Copper

- Extruded Dual Layer Polymer

- Temperature Rating -50°C to +120°C

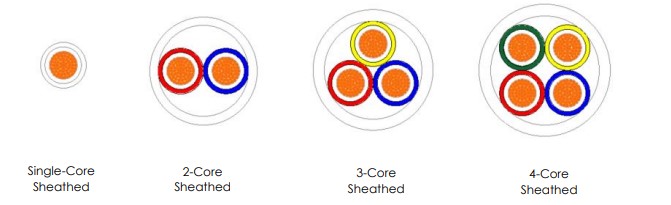

NXT99 - 600V Single Core Unscreened Def Stan 61-12 Part 18:

- Stranded Tinned Annealed Copper

- Flame retardant crosslinked Polymer

- Low flammability and low smoke and gas generation

- Temperature Rating -50°C to +120°C

Aerospace 55XL

- Def Stan 61-12 Part 33/001

- Aircraft Wiring

- Insulation Crosslinked ETFE, single or dual layer

- Stranded Tin, Silver or Nickel Plated conductor

- Crosslinked ETFE Jacket, White

- 600 VAC

- 135°C or 150°C

Def Stan 02-526:

- Dual extrusion insulation

- Halogen free inner layer

- High resistance to fluids, fuel and lubricating oil

- Temperature rating -30°C to +105°C, upper limit of prolonged usage 90°C

- Used in power, lighting, control and communications and instrumentation circuits for ships and submarines

Def Stan 02-527:

- Limited Fire Hazard Sheath

- Retains power to critical life support systems for up to 3 hours

- High resistance to fluids, fuel and lubricating oil

- Silicon insulation and glass fibre braid

- Used in power, lighting, control and communications and instrumentation circuits for ships and submarines

Abbreviations and commonly used terms:

02-526 | Limited Fire Hazard Standard |

02-527 | Fire Survival Standard |

DE or Def-Stan | Defence Standard |

Fire Survival | Can remain operational in the event of a fire for up to 3 hours |

LFH | Limited Fire Hazard cable, produces less toxic fumes and smoke for use in enclosed spaces |

MoD | Ministry of Defence |

NES | Naval Engineering Standard |

NSN | Nato Stock Number |

Multi Core Def-Stan 61-12 Pt18

Multi Core Def-Stan 61-12 Pt18

.png)