Cookies help us deliver our services. By using our services, you agree to our use of cookies.

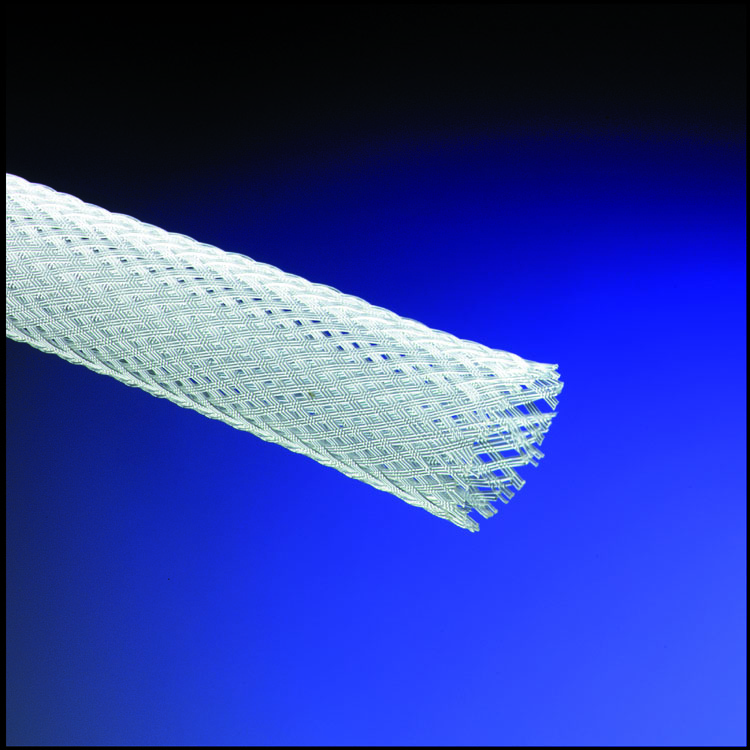

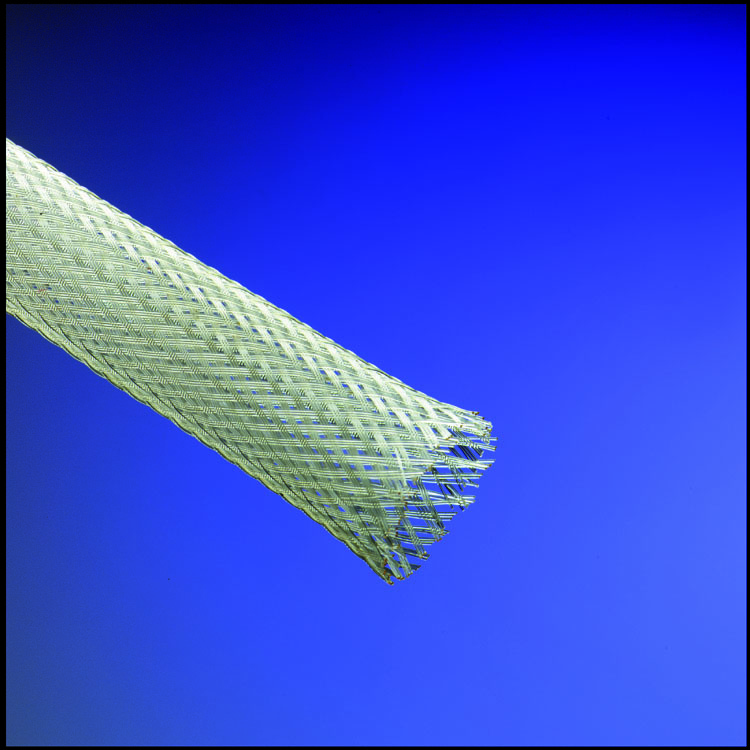

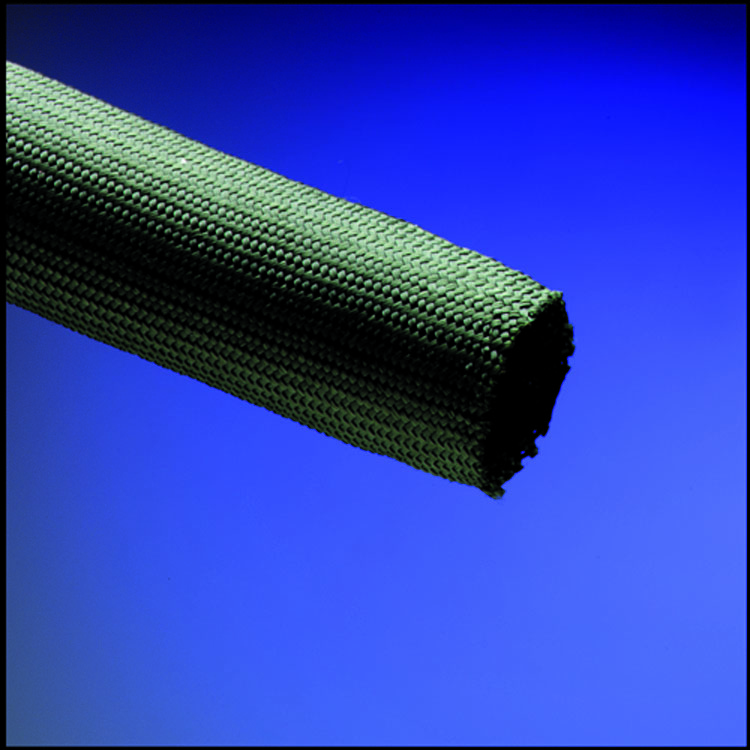

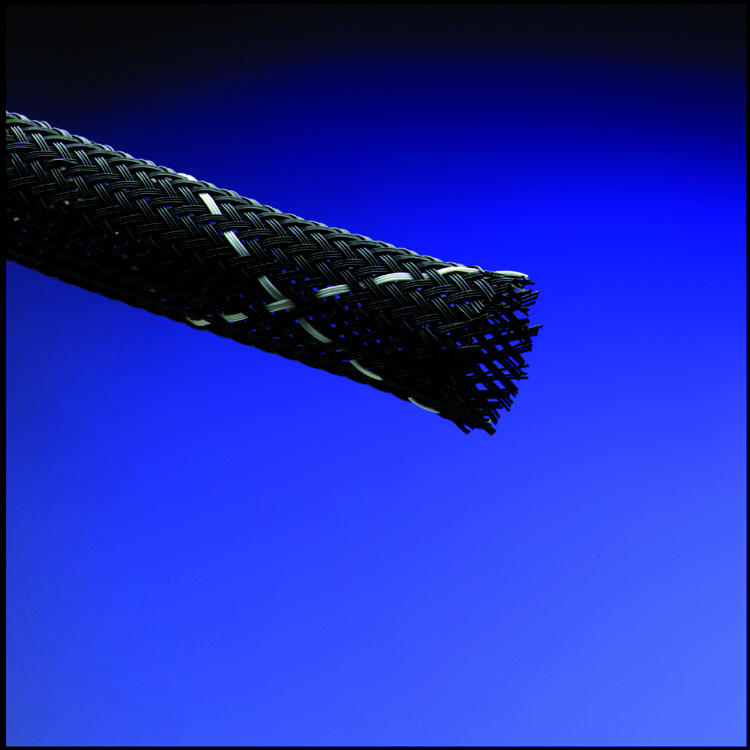

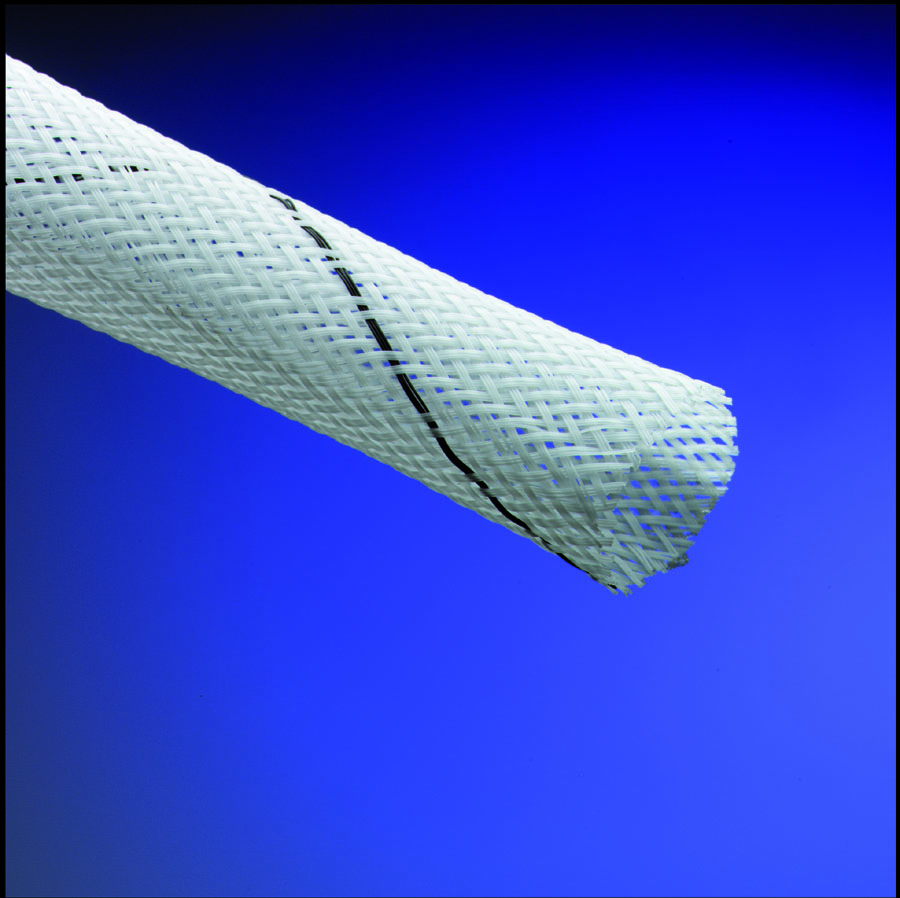

Expandable Sleeving

Western Filament’s expandable sleeving provides reliable protection for wires, harnesses, hoses, and cables.

Lightweight and flexible, made from self-moulding materials, they conform to the shape of the underlying components. Sleeving enhances abrasion resistance and helps prevent damage from impact, cuts, and snagging.

Products are available in a range of materials including Polyester, Halar®, Teflon ®, Kevlar® and Fibreglass.

Expand-A-Flex Polyester (Type P) PT/PT:

- Good chemical and abrasion resistance

- Operating temperatures: -70C/+125C

- UL1441 and CSA Certified Standard C22-2 Class 5836-01

- Made from Polyester Monofilament .010"

- For use in general manufacturing, automotive, telecommunication, industrial applications

Nomex®:

- High strength, solvent and abrasion resistance

- Operating temperature up to 350C

- Nomex® Synthetic Polyamide material

- Ideal for aerospace and aviation applications

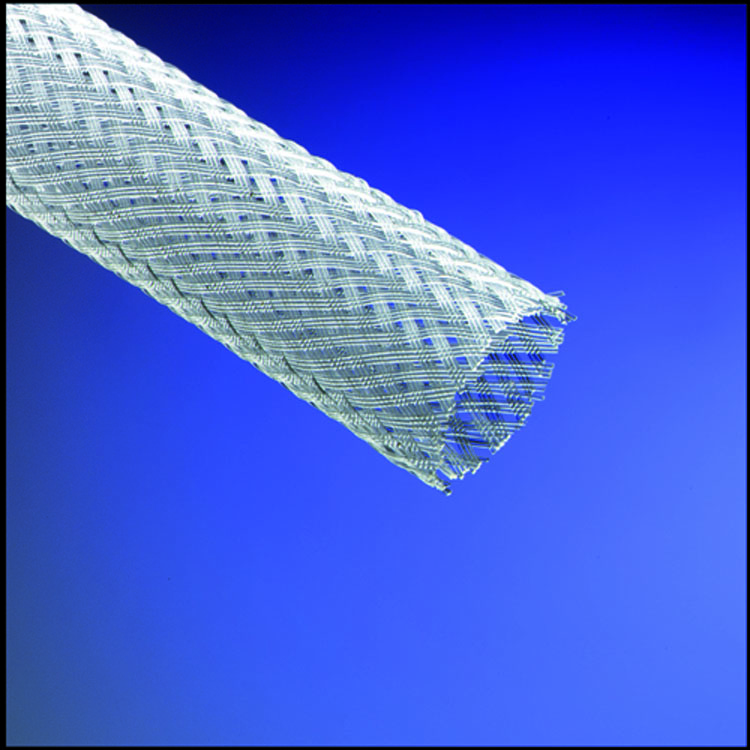

Expand-A-Flex Tight Weave (Type TW) PT/TW:

- High density and coverage with excellent abrasion resistance

- Operating temperature up to +125C

- Made from Polyester Monofilament .010"

- Recommend use where snag resistance, coverage, and protection are critical

Expand-A-Flex: Flame Retardant CT FR/FR:

- Self extinguishing, with chemical and abrasion resistance

- Operating temperature up to +125C

- VW1 UL1441 and CSA Certified Standard C22-Class 5836-0

- Made from Polyester Monofilament .009" or .010”

- Aviation, automotive, and space applications

Expand-A-Flex Flame Retardant light Weave FR/TW:

- Excellent abrasion resistance with flame retardant qualities

- Operating temperature up to +125C

- VW1 UL1441 and CSA Certified Standard C22-Class 5836-01

- Made from Polyester Monofilament .009" or .010”

- Suitable for harsh conditions including aviation, automotive, and space applications

Expand-A-Flex Halar® (Type H) HR/HR:

- Excellent chemical and abrasion resistance

- Operating temperature up to +150C

- VW1 UL1441 and CSA Certified Standard C22-Class 5836-01

- Material Halar® Monofilament .011

- Aviation, automotive, space and telecommunication applications.

Expand-A-Flex PEEK® HTP-250 (Type PK):

- A lightweight sleeving ideal as a replacement for Teflon

- Operating temperatures: - 70C/250C

- Made from Flame Retardant Polyetheretheketone .010"

- Ideal for industrial, aviation and space applications

Teflon ® Fluoro-Flex 500 (Type TF):

- Excellent abrasion and fluid resistance

- Operating temperatures: - 70C/250C

- Material: Teflon"' Monofilament .016"

- Ideal in aeronautical, space, electronic, industrial, marine and automotive applications

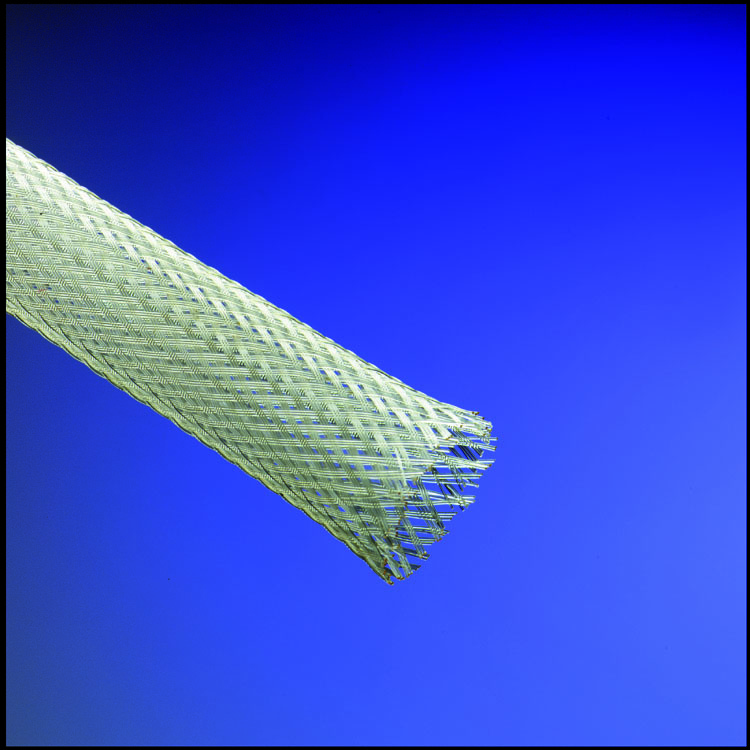

Expand-A-Flex Fiberglass:

- Good temperature resistance and not reactive to gasoline and alcohol

- Operating temperature up to 1100F

- For automotive and electrical applications

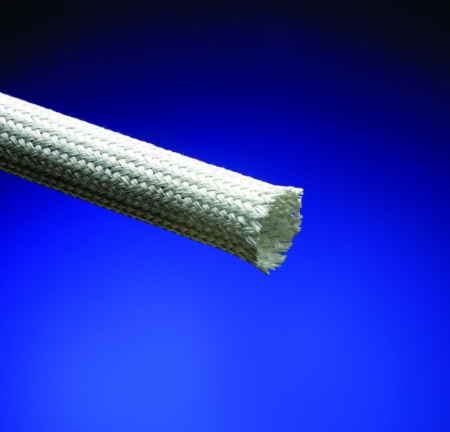

Kevlar®:

- Excellent heat and chemical resistance with added strength and minimum expansion

- Operating temperature up to 250C

- Kevlar® High Temp Resistant Aramid Fiber

- Ideal for aerospace and aviation

Ceramic (Nextel®):

- High temperature and abrasion resistance

- Made from Nextel 312 Ceramic

- Ideal for aerospace and aviation

Expandable Sleeving Catalogue

Expandable Sleeving Catalogue

.png)